From the rhythmic clatter of early industrial looms to the high-tech buzz of modern assembly lines, the journey of manufacturing has been nothing short of revolutionary. Today, as we stand at the brink of a new era, the concept of the ‘Connected Factory‘ emerges as a beacon of innovation in this ever-evolving landscape. Imagine a world where machines communicate seamlessly, where every cog and conveyor belt is a symphony of efficiency, orchestrated by advanced IT solutions. This isn’t just a futuristic fantasy; it’s the present reality of manufacturing, transforming factories into smart, interconnected hubs that redefine productivity and operational excellence. Welcome to the era of the Connected Factory, where technology is not just an enabler but a game-changer in the dynamic world of manufacturing.

Table of Contents

The Emergence of IT Solutions in Manufacturing

The manufacturing sector has undergone a profound transformation over the decades, evolving from labor-intensive manual processes to highly automated and efficient systems. This metamorphosis was significantly fueled by the advent and integration of Information Technology (IT). In the early days, manufacturing relied heavily on human skill and manual labor, with processes being time-consuming and often inconsistent in quality. The introduction of automation marked a significant shift, but it was the infusion of IT that truly revolutionized the industry.

IT solutions have redefined traditional manufacturing by introducing unparalleled precision, efficiency, and connectivity. From the implementation of computer-aided design (CAD) and manufacturing (CAM) to the utilization of complex enterprise resource planning (ERP) systems, IT has not only streamlined production processes but also enabled real-time monitoring and decision-making. These advancements have paved the way for more sophisticated production techniques, better quality control, and a more agile response to market demands, fundamentally transforming the manufacturing landscape into a smarter, more connected ecosystem.

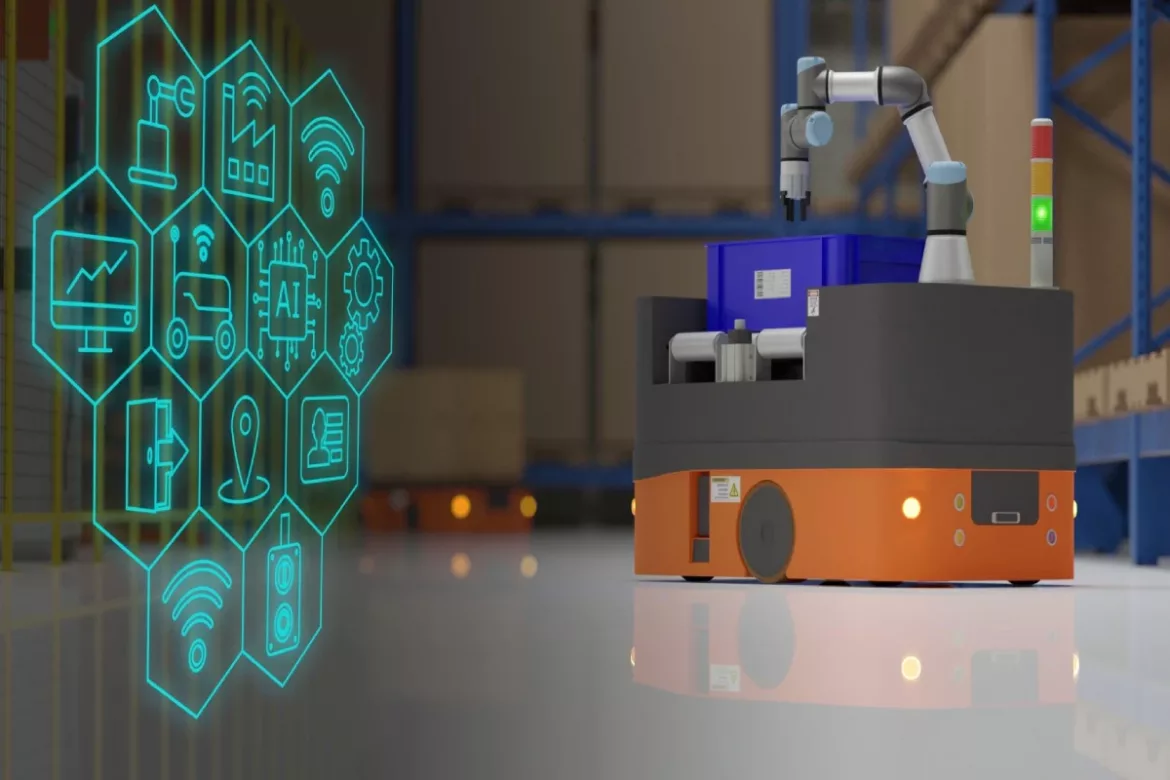

Key Components of a Connected Factory

Internet of Things (IoT) and its impact on manufacturing efficiency

In the heart of a connected factory lies the Internet of Things (IoT), a network of interconnected devices and machinery. IoT devices collect and exchange data, enabling manufacturers to monitor, analyze, and optimize production processes in real-time. This interconnectedness results in unprecedented efficiency, reducing downtime, enhancing production rates, and improving overall operational agility. By harnessing IoT, factories can anticipate maintenance needs, adjust production schedules on the fly, and ensure consistent product quality, marking a significant leap in manufacturing efficiency.

Cloud computing: Enabling real-time data analysis and decision-making

Cloud computing acts as the backbone of modern manufacturing, offering scalable and flexible data storage and processing capabilities. It allows for real-time data analysis and decision-making, empowering manufacturers to swiftly respond to changing market demands and operational challenges. Cloud platforms facilitate seamless integration of various factory systems, ensuring smooth information flow and collaboration across departments. This agility and efficiency in data handling enhance both strategic and operational decision-making processes in manufacturing.

Artificial Intelligence (AI) and Machine Learning (ML) in predictive maintenance and quality control

AI and ML are transforming predictive maintenance and quality control in manufacturing. These technologies analyze vast amounts of data from IoT sensors and cloud platforms to predict equipment failures before they occur, minimizing unplanned downtime. In quality control, AI-driven systems scrutinize products with a level of precision and consistency unattainable by human inspectors. This proactive approach to maintenance and quality assurance ensures continuous production and adherence to the highest quality standards, reinforcing the connected factory as a paragon of modern manufacturing.

Benefits of IT Solutions in Manufacturing

Increased productivity and efficiency

The implementation of IT solutions in manufacturing has led to a remarkable increase in productivity and efficiency. Automation driven by IT technologies has streamlined processes, reducing manual intervention and the potential for human error. This automation allows for faster production cycles and higher throughput, ensuring that more products are manufactured in less time and with greater consistency. Additionally, IT solutions enable better resource management and process optimization, contributing to leaner, more efficient operations that can adapt swiftly to changes in demand.

Enhanced quality control and waste reduction

IT solutions significantly enhance quality control in manufacturing. Advanced analytics and machine learning algorithms can detect even the slightest deviations in product quality, allowing for immediate corrections. This precision reduces the likelihood of defects, ensuring that products meet stringent quality standards. Moreover, better quality control naturally leads to less waste, as fewer resources are expended on reworking or discarding defective products. This not only saves material and labor costs but also aligns with sustainable manufacturing practices.

Real-time monitoring and predictive maintenance to minimize downtime

One of the most significant benefits of IT in manufacturing is the ability to perform real-time monitoring and predictive maintenance. By constantly analyzing data from various sensors and machines, IT systems can predict equipment failures before they happen. This foresight allows for maintenance to be scheduled during non-peak hours, significantly reducing unplanned downtime. Furthermore, real-time monitoring ensures that any potential issues are identified and addressed swiftly, keeping production lines running smoothly and efficiently. This proactive approach to maintenance is key in maximizing uptime and overall productivity in the manufacturing sector.

Conclusions

As we conclude, it’s clear that the role of IT solutions in manufacturing is not just transformative but essential in the modern era. The connected factory, powered by IoT, cloud computing, AI, and ML, is no longer a concept of the future; it’s a present-day reality shaping the manufacturing industry. The benefits – from skyrocketing productivity and efficiency to groundbreaking quality control and waste reduction – are tangible and compelling. Real-time monitoring and predictive maintenance are revolutionizing how manufacturing operates, minimizing downtime and maximizing output. For IT managers and business leaders in the manufacturing sector, embracing these technological advancements is not just a strategic move; it’s a leap towards future-proofing their operations in a rapidly evolving global market. As we embrace this digital revolution, the potential for growth and innovation in manufacturing seems limitless. The future is connected, and it’s here now.